close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

Choosing between tellurium copper rods and phosphor bronze rods is important. They are different in what they are made of and how they work. Tellurium copper has a little tellurium in it. This makes it easy to shape and good at carrying electricity. Phosphor bronze is a mix of copper, tin, and phosphorus. It is very strong, bends well, and does not rust easily. The table below shows the main differences:

Property | Tellurium Copper Rods | Phosphor Bronze Rods |

|---|---|---|

Composition | Copper + Tellurium | Copper + Tin + Phosphorus |

Machinability | High | Moderate |

Conductivity | Good | Good, lower than copper |

Corrosion Resistance | Moderate | Excellent |

Strength | Moderate | High |

Typical Application | Machined parts, connectors | Springs, bushings, electrical parts |

Knowing these differences helps people pick the right material. This is important for jobs that use brass, copper, or bronze parts.

Tellurium copper rods are simple to cut. They carry electricity very well. This makes them good for electrical parts like connectors and switches.

Phosphor bronze rods are very strong. They do not rust easily. They can bend without breaking. This makes them good for springs, bushings, and things used in the sea.

Use tellurium copper if you need good electrical flow. It is also easy to shape. Use phosphor bronze if you need something strong. It also does not rust much.

Phosphor bronze rods last longer in tough places like salty water. Tellurium copper works better in places that are not so harsh.

Always pick the right rod for your project. Think about strength, how well it carries electricity, if it resists rust, and if it is easy to shape. This helps you get the best results.

When you look at tellurium copper and phosphor bronze rods, you want to pick the right one. Both rods start with copper, but they have different uses and features. The table below shows the main differences:

Feature | Tellurium Copper Rods | Phosphor Bronze Rods |

|---|---|---|

Main Alloying Element | Tellurium | Tin, Phosphorus |

Base Metal | Copper | Copper |

Related Alloys | Brass, Bronze | Brass, Bronze |

Machinability | Excellent | Good |

Strength | Moderate | High |

Corrosion Resistance | Moderate | Excellent |

Electrical Use | Yes | Sometimes |

Common Applications | Electrical connectors, switches | Springs, bushings, gears |

Tip: People pick tellurium copper when they need something easy to cut and good for electricity. Phosphor bronze is better when you need something strong and that does not rust.

Tellurium copper has a little tellurium in it. This makes it easier to cut than copper or brass. It still carries electricity well.

Phosphor bronze mixes copper with tin and phosphorus. This makes it stronger than copper or brass. It also does not wear out or rust as fast as other copper alloys.

Brass is another copper alloy used in some of the same ways. But brass is not as strong as bronze. It is also not as easy to cut as tellurium copper. People use brass for things like decorations, plumbing, and musical instruments.

Tellurium copper is a special kind of copper alloy. It has a little bit of tellurium mixed in. This small amount changes how the metal acts. Most of it is still copper. The tellurium helps make it easier to cut and shape. Many companies use this alloy for its good features. It is easy to machine and keeps copper's best parts.

Note: Tellurium copper rods are picked when you need something that carries electricity well and is easy to cut.

Tellurium copper must follow strict rules for what goes in it. Groups like ASTM and ISO make these rules. The table below shows what is usually inside:

Alloying Element | Typical Composition Range (mass %) |

|---|---|

Copper (Cu) | ≥ 99.90% |

Tellurium (Te) | 0.40 – 0.70% |

Phosphorus (P) | 0.004 – 0.012% |

The UNS system puts tellurium copper in its own group. It is not part of the usual copper types. This helps makers keep the same quality everywhere.

Tellurium copper keeps most of copper's good traits. It lets electricity flow very well. It also fights rust better than plain copper, even in tough places. The table below lists some key facts:

Property | Value | Description/Notes |

|---|---|---|

Density | 8.7 g/cm³ | Normal for this alloy |

Hardness | Hv110 - Hv140 | Good for cutting and shaping |

Electrical Conductivity | 98% IACS | Almost as good as pure copper |

Thermal Conductivity | 200 W/m·K | Moves heat well |

Fatigue Resistance | Good | Handles stress over and over |

Ductility | Good | Can be shaped into many forms |

Weldability | Good | Good for making parts |

Corrosion Resistance | Better than copper | Works well in salty water |

Engineers use tellurium copper when they need something easy to cut but still good at carrying electricity. It is used for connectors, switches, and other parts that need to be strong and conduct electricity. The mix of copper and tellurium gives it special features that are hard to find in other materials.

Phosphor bronze is a strong copper alloy. It has copper, tin, and a little phosphorus. Makers pick it because it is tough and lasts long. Many industries use tin-phosphor bronze rods for important parts.

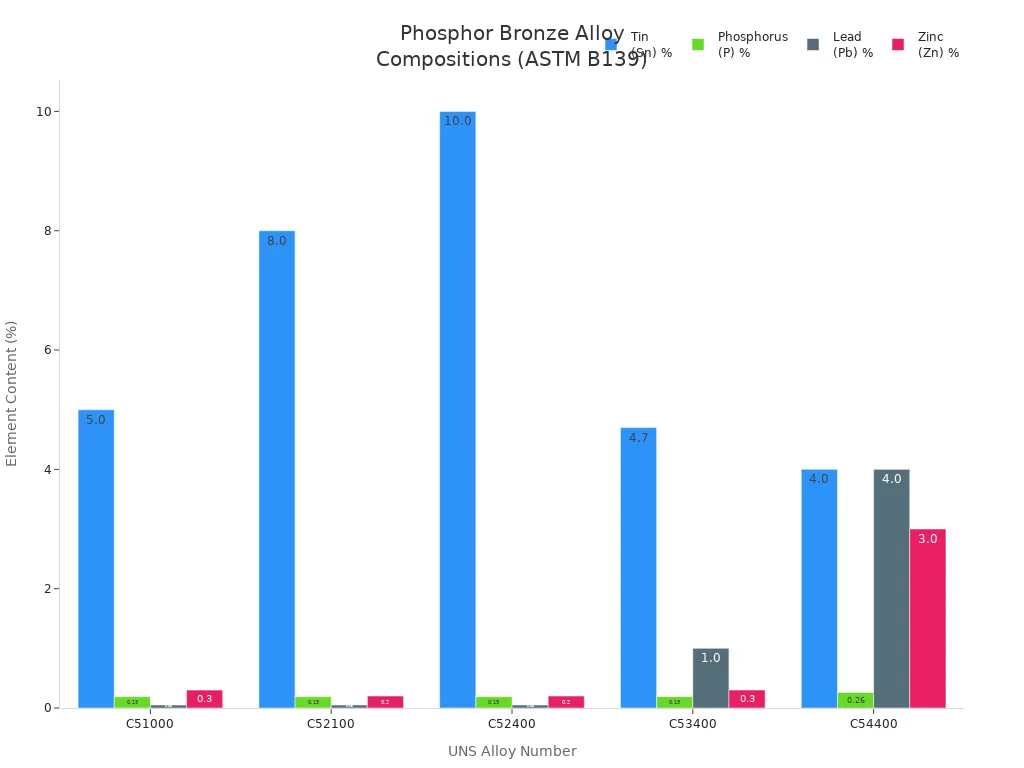

The main elements in these rods must meet strict rules. ASTM B139 gives the types. The table below shows what is inside some common alloys:

UNS No. | Tin (Sn) % | Phosphorus (P) % | Lead (Pb) % | Zinc (Zn) % | Iron (Fe) max % | Copper (Cu) % (balance) |

|---|---|---|---|---|---|---|

C51000 | 4.2 - 5.8 | 0.03 - 0.35 | ≤ 0.05 | ≤ 0.30 | ≤ 0.10 | Remainder |

C52100 | 7.0 - 9.0 | 0.03 - 0.35 | ≤ 0.05 | ≤ 0.20 | ≤ 0.10 | Remainder |

C52400 | 9.0 - 11.0 | 0.03 - 0.35 | ≤ 0.05 | ≤ 0.20 | ≤ 0.10 | Remainder |

Tin-phosphor bronze rods are strong and bend well. They do not rust, even in water or salty air. The table below lists their main features:

Property | Value/Range | Description/Notes |

|---|---|---|

Tensile Yield Strength | 380-450 MPa | Stronger than many other bronze alloys. |

Modulus of Elasticity | 110 GPa | Stiff, but not as much as steel. |

Electrical Conductivity | ~15% of pure copper | Lower than copper, but still useful for electrical parts. |

Hardness (Rockwell B) | 75-85 | Harder than pure copper. |

Density | ~8.8 g/cm³ | Typical for copper-tin alloys. |

Workability | Hot/cold worked, heat treatable | Can be shaped and treated for different uses. |

Additional Properties | Good fatigue resistance, corrosion resistance, spring characteristics | Makes it ideal for springs and marine parts. |

Phosphor bronze rods stay in shape under pressure. They do not snap or bend fast. Engineers use them for springs, gears, and bushings.

Tin-phosphor bronze rods are good for electrical connectors too. They last longer than many other bronze rods. Their mix of copper, tin, and phosphorus gives them strength, flexibility, and rust resistance.

Electrical conductivity tells us how well electricity moves through something. Tellurium copper rods let electricity flow almost as well as pure copper. Phosphor bronze rods do not let electricity move as easily. Tin and phosphorus in phosphor bronze slow down the electrons. This makes phosphor bronze not the best for strong electrical parts.

Alloy Type | Electrical Conductivity (% IACS) | Electrical Conductivity (Siemens/m) |

|---|---|---|

Tellurium Copper (C14500) | 90–95% | ~54,000,000 S/m |

Phosphor Bronze (C93600) | 11% | 6,400,000 S/m |

Pure Copper | 100% | 58,000,000 S/m |

Tellurium copper rods are used in connectors and switches. They have high electrical conductivity, almost like pure copper. Phosphor bronze rods are not as good for this. They are better when you need strength more than conductivity.

Thermal conductivity is also important. It shows how well a rod moves heat. Tellurium copper rods move heat better than phosphor bronze rods. Pure copper is the best, but tellurium copper is still good.

Material | Temperature (°C) | Thermal Conductivity (W/m·K) |

|---|---|---|

Tellurium Copper (proxy value) | 20 | ~80 |

Phosphor Bronze (C52400, 10% Sn) | 20 | 50 |

Pure Copper | 0 | 401 |

Tip: If you need something that moves electricity or heat well, pick tellurium copper rods.

Strength means how much force a rod can take before it bends or breaks. Phosphor bronze rods are very strong. Tin and phosphorus make them harder. Tellurium copper rods are not as strong. They are softer, so they are easier to shape and cut.

Material | Condition/Grade | Hardness Type | Typical Hardness Value |

|---|---|---|---|

Tellurium Copper (C14500) | H02 (Half Hard) | Brinell (BHN) | 76 |

Tellurium Copper (C14500) | H04 (Hard) | Brinell (BHN) | 81 |

Phosphor Bronze (C54400) | - | Rockwell B | 86 |

Phosphor Bronze (C52100) | - | Rockwell B | 93 |

Phosphor Bronze (C51000) | - | Rockwell B | 87 |

Phosphor bronze rods do not bend or snap easily. They are used in springs, gears, and bushings. Tellurium copper rods are not as strong, but they still work for many jobs.

Phosphor bronze rods: Very strong, good for moving parts.

Tellurium copper rods: Not as strong, good for parts made by machines.

Machinability means how easy it is to cut, drill, or shape a rod. Tellurium copper rods are very easy to machine. They are almost as easy as leaded brass. Phosphor bronze rods are also good, but not as easy as tellurium copper.

Alloy | Machinability Rating | Notes |

|---|---|---|

Tellurium Copper | Excellent (like leaded brass) | Excellent machinability, easy to cut and shape |

Phosphor Bronze | High | Good machinability, but not as high as tellurium copper or brass |

Brass | Excellent | Used as a standard for machinability |

Tellurium copper rods help machines work faster and keep tools sharp longer. This saves time and money. Phosphor bronze rods are still good, but they can wear out tools faster.

Note: If you need something easy to machine, pick tellurium copper rods or brass rods.

Corrosion resistance means how well a rod stands up to rust and chemicals. Phosphor bronze rods are great at fighting rust. They last a long time in water, salty air, and even some acids. Tellurium copper rods are better than pure copper, but not as good as phosphor bronze.

Material | Corrosion Resistance | Typical Use Environment |

|---|---|---|

Tellurium Copper | Moderate to Good | General, some marine, not harsh |

Phosphor Bronze | Excellent | Marine, industrial, outdoor |

Brass | Good | Plumbing, decorative, indoor |

Phosphor bronze rods are used in boats, springs, and bushings. They do not rust or wear out fast. Tellurium copper rods are used in places that are not too harsh. Brass rods also fight rust, but not as well as bronze rods.

Phosphor bronze rods: Best for wet or salty places.

Tellurium copper rods: Good for dry or mild places.

Brass rods: Good for inside or for looks.

Engineers choose phosphor bronze rods when they need the best rust protection and long-lasting parts.

Tellurium copper rods are used in many industries. They are good for electrical and electronic jobs. This is because they carry electricity well and are easy to cut. Companies use these rods for things like:

Electrical connectors and switches

Motor and switch parts

Transistor bases

Tips for plasma cutting and welding torches

Plumbing fittings

Electrodes for machines

These jobs need rods that are strong and do not wear out fast. They also need rods that can be welded easily. Most tellurium copper rods are used in electrical and electronics work. Car, airplane, and green energy companies also use them. There are different types, like C145 and C180, for special jobs. C145 is good for connectors and welding torch tips. C180 works well for plumbing and electrodes. More people want these rods as electric cars and green energy grow.

Tellurium copper rods help machines cut quickly and keep tools sharp. But sometimes, they do not last as long as pure copper when cutting.

Phosphor bronze rods are used for many things. They are strong, bend well, and do not rust. This makes them good for hard jobs. The table below shows where they are used and why:

Application Category | Specific Uses | Key Properties |

|---|---|---|

Bearings | Fast machines, heavy equipment | Wear resistance, self-lubrication |

Bushings | Car engines | Strength, lasts long |

Connectors | Wires, circuit boards | Conducts electricity, resists rust |

Springs | Factory springs | Bends well, does not break easily |

Aerospace Components | Engine parts, landing gear | Strong, handles heat |

Marine Applications | Boat propellers, fittings | Does not rust |

People also use them for welding rods, jewelry, guitar strings, and dental bridges. Phosphor bronze rods work well in pipes for wires and in places with strong chemicals. They do not rust or wear out fast, so they are great for boats and tough jobs. In springs and bearings, they last a long time and work well.

Phosphor bronze rods are best where you need strength and no rust. They keep working in water, salty air, or high pressure.

Picking the best rod depends on what you need for your project. Each rod has its own special strengths. Tellurium copper is great if you need good electrical flow and easy cutting. Phosphor bronze is best if you want strong rods that do not rust. Engineers think about what the rod will do before they choose.

Here is an easy way to pick:

Need a rod that carries electricity well?

Pick tellurium copper. It lets electricity move almost like pure copper.

Need a rod that is strong and does not rust?

Choose phosphor bronze. It stays strong and keeps its shape in hard places.

Want a rod that is easy to cut into shapes?

Tellurium copper is easy to machine and helps tools last longer.

Need rods for springs, bushings, or gears?

Phosphor bronze is good for these because it is strong and bends well.

Tip: Always pick the rod that matches the main job. For electrical work, use rods with high conductivity. For moving parts, use rods that are strong and last long.

The table below shows the most important things to compare:

Performance Factor | Tellurium Copper Characteristics | Phosphor Bronze Characteristics |

|---|---|---|

Electrical Conductivity | High, 75%–90% IACS | Moderate, 25%–50% IACS |

Thermal Conductivity | High | Lower than tellurium copper |

Strength | Increased by alloying | Good, but generally less than tellurium copper |

Corrosion Resistance | Good, works in marine and freshwater | Excellent, especially in marine and freshwater |

Mechanical Properties | Good tensile strength, work hardening, springback | Similar, with good formability and mechanical behavior |

Some important things help decide how well and how long a rod will work. These things also help buyers pick the right rod for each job.

Mechanical Properties

How strong, hard, and bendy a rod is changes how long it lasts. Phosphor bronze is very strong and does not wear out fast. Tellurium copper is strong and can take stress many times.

Electrical Properties

How well a rod carries electricity matters for some jobs. Tellurium copper lets a lot of current flow. The outside of the rod also matters for coating and joining.

Alloy Composition

Small changes in what is mixed in can change how the rod works. Adding things like silver or chromium can make rods stronger or better at carrying electricity. Some things, like cadmium, help but may not be safe or allowed.

Dimensional Tolerances

Making sure rods are the right size helps parts fit together. Both copper and bronze rods can be made very exact for special uses.

Corrosion Resistance

Phosphor bronze does not rust in tough places. Tellurium copper is also good, but may not last as long in salty water.

Cost and Compliance

Some rods cost more because they use rare metals. Some metals are not allowed by rules. Buyers must think about price, how well the rod works, and safety.

The table below shows how these things change how well the rod works and how much it costs:

Key Factors | Description | Impact on Performance and Cost-effectiveness |

|---|---|---|

Mechanical Properties | Strength, hardness, ductility, fatigue strength | Durability, reliability, formability |

Electrical Properties | Conductivity, surface for plating/soldering | Functionality, manufacturing compatibility |

Alloy Composition | Additions like silver, chromium, cadmium | Improved properties, higher cost, regulatory issues |

Dimensional Tolerances | Precision in rod/bar dimensions | Compatibility with advanced processes |

Regulatory Considerations | Use restrictions on certain elements | Safety, compliance, cost |

Alloy Development Goals | Balance strength, conductivity, resistance, cost | Efficient solutions for specific industrial demands |

Note: Always check where and how the rod will be used before picking. The right rod saves money and works better.

Engineers usually follow these steps to pick a rod:

Find out what the rod will be used for.

Check if the place has things that cause rust.

Make sure the rod is strong enough and carries electricity well.

Think about cost, safety, and rules.

Pick the rod that fits all the needs best.

By doing these steps, teams can pick the best copper or bronze rod for any job.

Tellurium copper rods and phosphor bronze rods are used for different things. Tellurium copper is easy to cut and carries electricity well. Phosphor bronze is strong and does not rust easily. Recent research shows these facts:

Tellurium copper is great for making machine screws.

Phosphor bronze is good for springs, hardware, and electric parts.

Tellurium copper is easier to cut, but phosphor bronze is stronger and lasts longer.

Consideration | Tellurium Copper | Phosphor Bronze |

|---|---|---|

Machinability | Excellent | Moderate |

Corrosion Resistance | Good | Superior |

Strength | Moderate | High |

Typical Applications | Electrical components | Marine, mechanical parts |

People should pick the rod that fits their project best. This helps them get the best results.

Tellurium changes how copper acts inside the rod. This makes it easier for machines to cut the rod. Tools stay sharp longer when cutting it. Factories save time and money because of this.

Yes, they work well in water. Phosphor bronze does not rust or corrode easily. Many engineers use it for boat parts and marine gear.

Tellurium copper is best for electrical connectors. It carries electricity almost like pure copper. It is also easy to shape into small parts.

Phosphor bronze and tellurium copper rods can be safe for some plumbing jobs. Always check local rules before using them for food or water.